WAREHOUSE

SUPPORT

14 DAYS

experiences

Single-Disc Concrete Grinders

-

Toolsa GX 250 Concrete Polishing Grinder With Adjustable Speed And Tool

GX250TAAt your place tomorrow

zł7,380.00 tax incl. 6000,00 zł tax excl.View technical data

- Ciężar: 60 kg

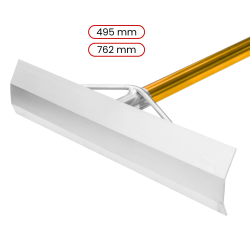

- Szerokość robocza: 250 mm

- Napięcie: 110 V | 230 V

- Częstotliwość: 50 Hz

- Wymiary: 833 × 355 × 1161 mm

Single-disc concrete grinders from TOOLSA.eu are compact and maneuverable machines designed for grinding, leveling, and removing coatings from concrete. They perform exceptionally well on small and medium-sized surfaces and in hard-to-reach areas.

In the single-disc concrete grinders category at TOOLSA.eu, you will find compact, efficient machines designed for small and medium-sized surfaces where precision, mobility, and ease of handling are essential. Single-disc grinders are perfect for floor renovation, surface leveling, and removing coatings, adhesives, and resin residues.

These machines are part of the concrete grinders range.

Applications of Single-Disc Grinders

Work in Restricted Spaces

Thanks to their compact design, single-disc grinders perform exceptionally well in corners, hallways, and along walls — areas where larger planetary machines cannot reach.

Coating and Adhesive Removal

With the right diamond segments, these grinders efficiently remove adhesives, paints, resins, and thin coatings without damaging the substrate.

Subfloor Preparation

Single-disc grinders perfectly level surfaces and remove laitance, which is essential before applying resins, self-levelling compounds, and other flooring systems.

Why Choose TOOLSA.eu Single-Disc Grinders?

✔ Easy operation – ideal for users who need a mobile and user-friendly machine.

✔ High versatility – compatible with a wide range of diamond segments and pads.

✔ Precision – excellent control on small or detailed surfaces.

✔ Compact construction – convenient for transport and work near walls and corners.

FAQ – Frequently Asked Questions

What are single-disc grinders best used for?

They are ideal for small to medium areas, edge work, and tasks requiring high precision— such as coating removal and substrate preparation.

How do I choose the right diamond segments?

The choice depends on the hardness of the concrete and the stage of the work:

- hard concrete – soft-bond segments,

- medium concrete – universal-bond segments,

- soft concrete – hard-bond segments,

- smoothing/polishing – high-grit diamond pads.

Do single-disc grinders generate a lot of dust?

Yes — which is why using an industrial vacuum cleaner connected to the grinder is highly recommended. It significantly reduces dust and improves working conditions.

Are these grinders suitable for beginners?

Yes — they are easier to operate than planetary machines and allow users to quickly master grinding techniques while maintaining high work quality.

Can they grind materials other than concrete?

Yes — with appropriate diamond tools you can also grind anhydrite, screed, and even some stones, although concrete remains their primary application.

Polski

Polski